Once released, the carriage can no longer support the tail end if the tube during a bend.

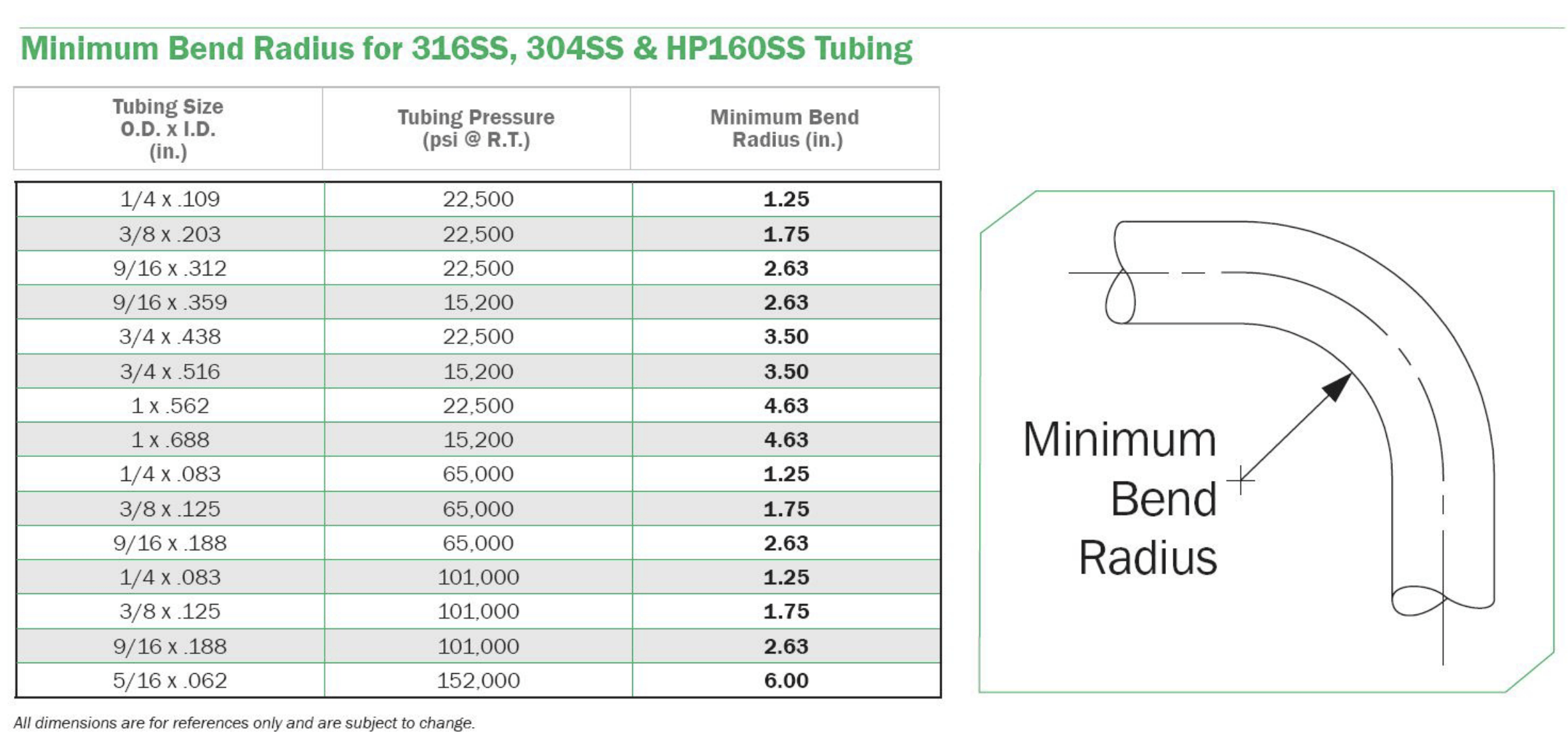

This situation is highlighted when a CNC tube bender’s carriage releases the tube before the last bend is made. (25.4 mm) Sharp Bend 1994 2009 Swagelok Company Slide-Chart by PERRYGRAF, L.A., 91324-3552 Printed in U.S.A. Therefore, adjusting the carriage to a greater CLR can sometimes eliminate wrinkles. This is due, in part, to the softness of some grades of copper. If the alignment of the carriage is too far away from the pressure die during bending (non-mandrel bending), then wrinkles may occur. This is because the aluminum can withstand greater compressive forces on the inside of a bend before the inside wall itself starts to wrinkle.Īlso, the position of the carriage on a CNC bender can influence wrinkles when bending copper. 035” wall can often be bent to a tighter radius then soft copper. There are six small radius die blocks, eleven large radius die blocks, three sizes of close bend radius blocks, and fourteen metric sizes. When bending copper, the compressive forces on the inside of the bend can tend to give way sooner as the centerline radius becomes smaller.Īs an example, a ؽ” aluminum tube with a. EXACTOL® 400 Series Tube Benders Radius Die Blocks Radius Die Blocks Radius die blocks can be furnished from stock in 34 sizes for standard bends ranging from 9/16' to 5' radii, as given in the chart below. The yield strength of the material being bent can directly influence whether there are wrinkles or no wrinkles. There are other factors that can influence the quality of a bend. However, for consistent production results, keeping the D of bend greater than 2 can disperse of several long-term headaches.

It is possible to bend the ½” diameter copper tube above to a smaller radius.

0 kommentar(er)

0 kommentar(er)